Cold chain logistics is a critical element in the safe transport and storage of biopharmaceutical products, especially for clinical trials. For drugs, vaccines, and biological samples, maintaining strict temperature control throughout the supply chain ensures that the products retain their efficacy and safety, ultimately safeguarding the success of clinical trials. This blog delves into the key elements of cold chain logistics and the various solutions necessary to preserve the integrity of biopharmaceutical shipments.

The Crucial Role of Cold Chain Logistics in Biopharmaceutical Shipments

The term cold chain logistics refers to the process of maintaining a controlled temperature environment for products during transportation and storage. For biopharmaceuticals, such as vaccines, biologics, and clinical trial drugs, cold chain management is not optional—it is a necessity! If the temperature fluctuates outside the designated range, the integrity of the product can be compromised, potentially resulting in clinical trial failures, adverse effects, or even harm to patients.

Effective cold chain logistics involves a coordinated effort between temperature-controlled packaging, precise monitoring, and compliance with strict regulatory standards. Maintaining the required temperature throughout the journey—from the point of manufacture to the clinical trial site—is vital for preserving the quality and efficacy of biopharmaceutical products.

Temperature-Controlled Packaging: Protecting Biopharmaceutical Integrity

A critical component of cold chain logistics is the use of temperature-controlled packaging. Whether it’s refrigerated containers, insulated boxes, or thermal blankets, the right packaging ensures that temperature-sensitive products remain at the required temperature range.

For clinical trials, the stakes are even higher. A minor lapse in temperature could invalidate the trial, delay research timelines, and cause loss of valuable medical data. Temperature-controlled packaging safeguards the integrity of clinical trial materials, ensuring that drugs, vaccines, and biological samples stay within their optimal temperature range.

Some solutions include:

- Insulated containers to maintain consistent temperatures.

- Thermal blankets to provide additional temperature stability.

- Refrigerated pallets for larger shipments.

These packaging solutions are designed to minimise the impact of external temperature fluctuations and maintain the required environment for biopharmaceutical products.

Real-Time Tracking and Monitoring Systems

One of the most significant challenges in cold chain management is ensuring constant monitoring of temperature conditions. This is where real-time tracking becomes invaluable. By integrating GPS and data loggers into the logistics process, stakeholders can track the temperature and location of their shipments at any given time.

Temperature-sensitive products are particularly vulnerable during long-haul shipping or when moving through multiple distribution points. Real-time tracking ensures that if a deviation occurs, corrective action can be taken immediately, mitigating risks to the products’ integrity.

Additionally, temperature-controlled courier services are equipped with advanced monitoring systems, allowing pharmaceutical companies to keep an eye on the temperature conditions throughout the entire shipment process. This level of visibility and control provides peace of mind, ensuring compliance with regulatory standards.

Regulatory Compliance for Clinical Trials and Biopharmaceuticals

Regulatory compliance is a cornerstone of cold chain logistics in the biopharmaceutical industry. There are strict guidelines that govern the handling, transport, and storage of temperature-sensitive products. Regulations such as Good Distribution Practices (GDP) and Good Manufacturing Practices (GMP) are designed to ensure that biopharmaceutical products are not exposed to harmful conditions that could affect their quality.

In the context of clinical trials, maintaining compliance with these standards is crucial for avoiding potential legal consequences and ensuring the success of the trial. From temperature monitoring to documentation, every aspect of the cold chain process must adhere to these stringent regulations.

Documentation plays a key role in this process. Accurate records of temperature logs, packaging methods, and any deviations during transit must be maintained. These records not only prove compliance but also provide transparency throughout the shipping process.

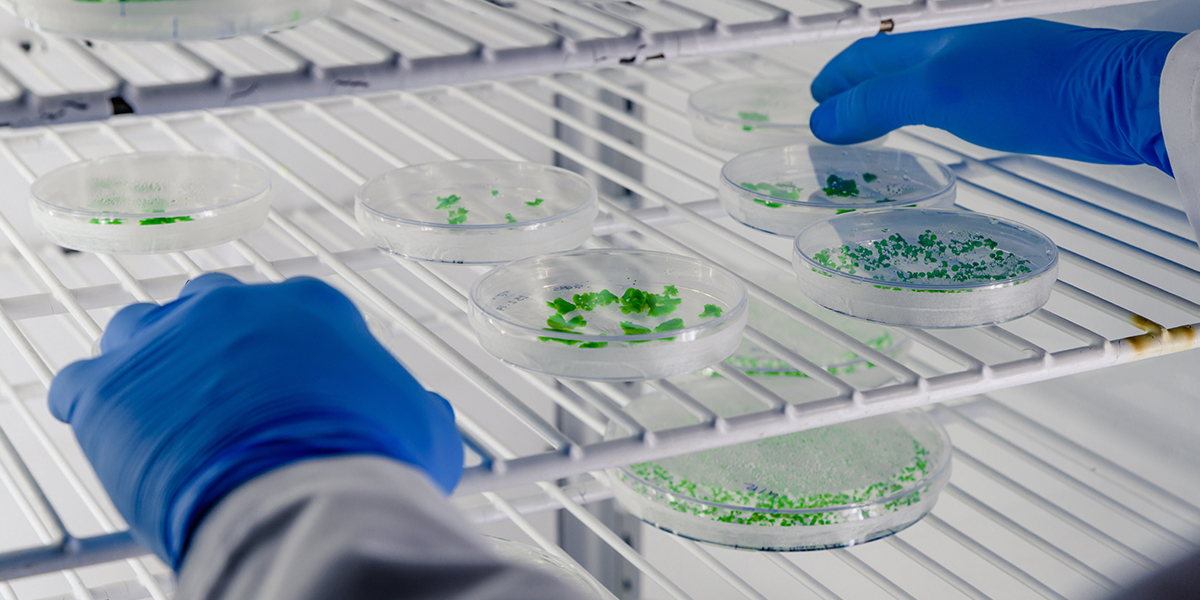

The Importance of Cold Chain Logistics for Biological Samples

In addition to drug shipments, biological samples are another category of products that require rigorous cold chain management. These can include vaccines, blood samples, tissue samples, and other biopharmaceutical materials. Biological samples are often more sensitive to temperature fluctuations than finished products, as they can lose their efficacy, undergo molecular degradation, or become contaminated.

Cold logistics for biological samples involves even more stringent controls to ensure that temperatures are consistently maintained and that the samples remain viable for their intended purpose. The use of temperature-controlled storage, coupled with real-time temperature monitoring, ensures that biological samples retain their integrity from collection to analysis.

How CoolReach Logistics Supports Cold Chain Integrity

CoolReach Logistics offers a comprehensive suite of cold chain logistics services designed to preserve the integrity of biopharmaceutical products throughout the supply chain. With decades of experience in biopharmaceutical logistics, we specialise in handling the most time critical and temperature sensitive shipments, from clinical trial drugs, biological samples, ATMP Cell & Gene samples, API to commercial finished drug materials.

At CoolReach, we prioritise:

- Advanced temperature-controlled packaging: Tailored solutions to meet the specific needs of clinical trial materials and pharmaceutical shipments.

- Real-time temperature monitoring: Cutting-edge technology to provide end-to-end tracking and alerts for temperature deviations.

- Regulatory compliance: Adherence to all relevant regulations, including GDP and GMP, to ensure the safe transport of biopharmaceuticals and clinical trial materials.

- Custom solutions: We offer flexible, personalised services to meet the unique needs of our clients, ensuring timely and secure deliveries.

Our temperature-controlled logistics services are designed to meet the rigorous demands of the pharmaceutical industry, providing reliable, efficient, and compliant logistics solutions for clinical trials and biopharmaceutical shipments worldwide.

Conclusion

The integrity of biopharmaceutical shipments, particularly in clinical trials, is of utmost importance. Cold chain logistics plays a crucial role in preserving the safety, efficacy, and compliance of drugs, vaccines, and biological samples. By utilising advanced temperature-controlled packaging, real-time monitoring, and adhering to stringent regulatory standards, companies can ensure that their products remain safe throughout the entire supply chain.

At CoolReach Logistics, we are dedicated to providing clinical trial supply services and biopharmaceutical logistics solutions that safeguard the integrity of your temperature-sensitive materials. With our expertise in cold chain management, you can trust that your products will reach their destination safely, maintaining their full potency and effectiveness.