The Science Behind Cold Chain Packaging

How Packaging Maintains Temperature Integrity

Maintaining the integrity of temperature-sensitive shipments is crucial in cold chain logistics. Advanced temperature-controlled packaging plays a pivotal role in preserving the efficacy of pharmaceuticals by minimising temperature fluctuations. The science behind these solutions involves the use of phase change materials and insulation technologies that create a stable environment for sensitive products.

Key Technologies: Insulated Containers and Thermal Blankets

Insulated containers and thermal blankets are at the forefront of cold chain packaging solutions. These technologies provide superior thermal protection, reducing the risk of temperature excursions. Thermal blankets offer an additional layer of insulation, protecting products during transit, while insulated containers ensure consistent internal temperatures.

Additionally, these solutions are critical for maintaining the required temperature range for sensitive products, preventing spoilage and extending shelf life. Insulated containers are designed to withstand various external conditions, ensuring the stability of temperature-sensitive products throughout the journey.

CoolReach’s Advanced Packaging Solutions

Overview of the “Temptale Ultra” Data Logger

CoolReach employs the “Temptale Ultra” data logger, a cutting-edge device that monitors and records temperature data in real time. This technology provides visibility and control, ensuring that all temperature-controlled logistics remain within specified parameters. Clients benefit from detailed reports that guarantee compliance and quality.

The “Temptale Ultra” also supports temperature monitoring, which is essential for maintaining the integrity of the entire cold supply chain. By offering precise data on temperature and humidity levels, this device ensures that every shipment meets stringent quality standards.

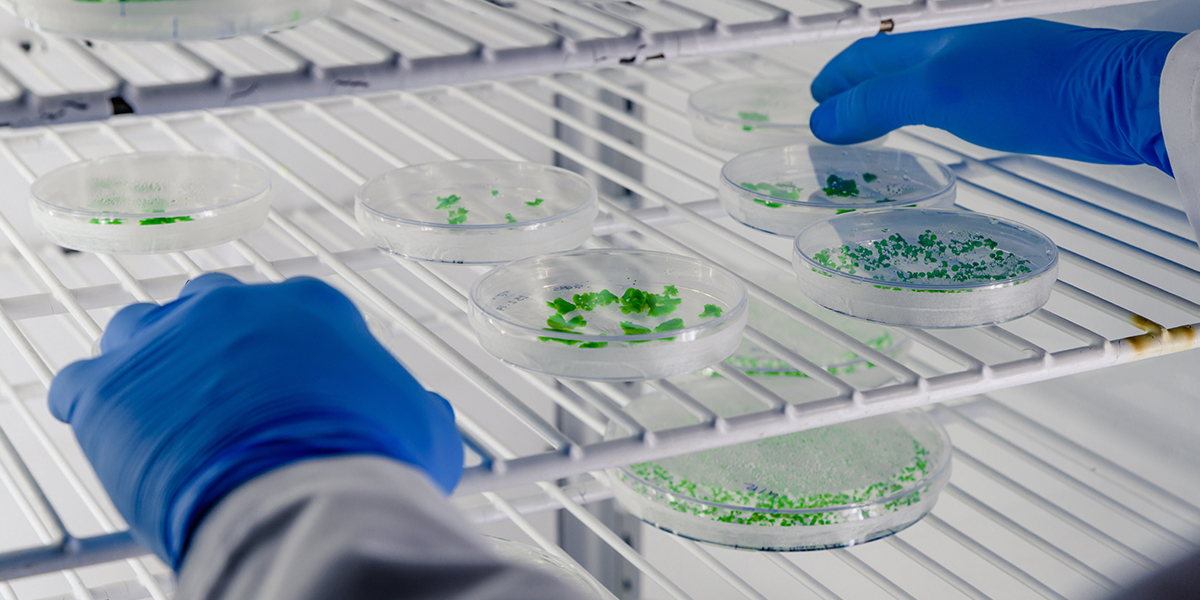

Customisable Packaging for Specific Biopharmaceutical Needs

CoolReach offers customisable packaging solutions tailored to the unique needs of each biopharmaceutical shipment. Whether it’s for vaccines, biologics, or other sensitive products, their advanced packaging systems are designed to meet specific temperature requirements, enhancing the overall efficiency of pharmaceutical logistics.

These solutions are adaptable to various cargo types, ensuring that perishable goods are transported safely and efficiently. Customisation allows for the seamless integration of packaging with the broader supply chain, ensuring that products maintain their integrity from origin to destination.

Sustainable Packaging Trends in the Cold Chain

Sustainability is a growing trend in cold chain management. CoolReach integrates eco-friendly temperature-controlled packaging solutions, such as recyclable materials and reusable containers. These innovations not only reduce the environmental footprint but also align with global sustainability goals.

Incorporating these sustainable practices helps CoolReach stay ahead in the competitive logistics market, providing clients with environmentally responsible options that do not compromise on performance.

Ensuring Quality and Compliance with Packaging

Meeting Regulatory Standards for Cold Chain Logistics

Adherence to strict regulatory standards is essential in pharmaceutical transport. CoolReach ensures that all packaging solutions meet international guidelines such as GDP (Good Distribution Practices). This commitment to compliance guarantees the safety and efficacy of biopharmaceutical products.

CoolReach’s expertise in cold chain logistics service ensures that every aspect of packaging and transport adheres to these regulations, providing peace of mind for clients across the globe.

Implementing Robust Quality Assurance Protocols

CoolReach’s quality assurance protocols are designed to monitor every aspect of the packaging process. From initial design to final delivery, these protocols ensure that all cold chain packaging solutions adhere to the highest standards, mitigating risks and ensuring product integrity.

By leveraging a robust quality assurance framework, CoolReach maintains the reliability of its logistics services, ensuring that every shipment meets the highest standards of safety and performance.

The Future of Packaging in Cold Chain Logistics

Innovations Driving Better Efficiency and Sustainability

The future of cold chain logistics is marked by innovations that enhance efficiency and sustainability. Emerging technologies such as smart sensors and sustainable materials are driving the evolution of advanced logistics solutions, enabling more reliable and eco-friendly transport options.

These advancements are crucial for managing the complexities of the entire supply chain, ensuring that each link functions optimally to support the seamless delivery of temperature-sensitive goods.

The Role of AI and IoT in Packaging Solutions

AI and IoT are transforming temperature-controlled logistics by providing predictive analytics and real-time monitoring. These technologies enable proactive management of the cold chain, ensuring that packaging solutions adapt dynamically to changing conditions, further improving reliability and efficiency.

As AI and IoT continue to evolve, they will play an increasingly significant role in the logistics market, driving innovations that enhance both operational efficiency and customer satisfaction.

Conclusion

CoolReach is at the forefront of innovation in cold chain logistics, offering state-of-the-art packaging solutions that ensure the safe and efficient delivery of biopharmaceutical products. By leveraging advanced technologies, sustainable practices, and a commitment to quality, CoolReach not only meets but exceeds industry standards, setting a new benchmark for pharmaceutical logistics.

For more insights on our services, explore our Premium Temperature-controlled Courier solutions.