The Role of Temperature Control Logistics in Pharma Manufacturing

In the pharmaceutical industry, maintaining the integrity of raw materials, active pharmaceutical ingredients (APIs), and finished drug products is critical. Temperature control logistics ensures that these products are transported under precise conditions to prevent degradation, compliance violations, and financial losses. Without robust cold chain logistics, pharmaceuticals are at risk of losing efficacy, posing significant risks to patient safety and regulatory compliance.

Temperature control logistics plays a crucial role in pharmaceutical manufacturing, requiring strict regulatory adherence, optimised supply chain strategies, and advanced cold chain logistics solutions to maintain drug stability and quality throughout distribution. These elements are essential for ensuring compliance and product integrity.

Why Temperature Control Logistics is Critical in Pharmaceutical Production

Temperature fluctuations in pharma logistics can have severe consequences, impacting product stability and rendering medications ineffective. The industry is governed by strict regulations, including MHRA (Medicines and Healthcare products Regulatory Agency) and GDP (Good Distribution Practice) compliance, which mandate stringent controls over storage and transport conditions.

Pharmaceutical products must be transported within a temperature-controlled environment, ensuring compliance with regulatory standards and minimising risks such as:

- Product degradation: Exposure to incorrect temperatures can alter chemical compositions.

- Regulatory non-compliance: Failure to meet GDP standards can result in fines and product recalls.

- Financial loss: Damaged products contribute to significant economic setbacks for manufacturers and distributors.

- Patient health risks: Improperly stored or transported medicines can lead to ineffective treatments, worsening health conditions, and, in severe cases, life-threatening consequences for patients.

By implementing cold chain logistics best practices, pharmaceutical companies can mitigate these risks while maintaining the integrity of their supply chain.

Cold Chain Logistics for Raw Materials and APIs

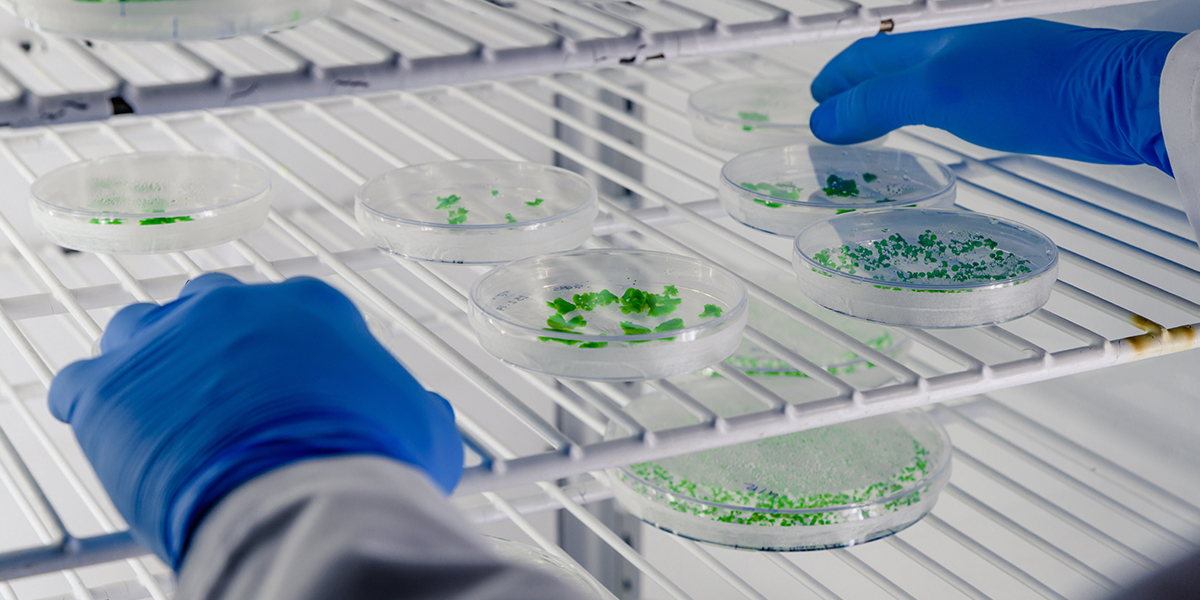

The production of pharmaceuticals begins with raw materials and APIs, which require stringent storage and temperature-controlled transportation conditions to maintain their potency. Cold chain logistics solutions are essential for preventing contamination and degradation during transit.

Preventing Contamination and Degradation

APIs and raw materials are highly sensitive to environmental changes. Exposure to extreme temperatures, humidity, or improper handling can result in chemical instability, microbial growth, or contamination. To ensure product integrity, pharma manufacturers must invest in:

- Temperature-controlled storage facilities for raw materials before production.

- Validated temperature monitoring systems that track fluctuations in real time.

- Stringent quality control measures to prevent cross-contamination.

- Proper handling and training protocols to ensure staff are equipped with knowledge of temperature-sensitive handling requirements.

- Backup power and fail-safe mechanisms in storage facilities to prevent temperature excursions in case of power failures.

Temperature Control Packaging Solutions for Active Ingredients

Temperature control packaging plays a crucial role in securing APIs and raw materials during transit. The use of insulated packaging, phase change materials (PCMs), and active cooling systems ensures stable temperature conditions. Solutions include:

- Cryogenic containers for ultra-low temperature storage, essential for biologics and vaccines.

- Passive temperature control packaging with PCM packs for maintaining stable temperatures during short-haul deliveries.

- Active temperature-controlled containers equipped with real-time tracking and temperature regulation for long-distance shipping.

With customised temperature control packaging, pharmaceutical companies can enhance safety, reduce waste, and comply with international cold chain logistics standards.

For a deeper dive into advanced packaging innovations, explore our blog: Advanced Packaging Innovations in Cold Chain Logistics

Transporting Finished Drug Products in Pharma Logistics

After pharmaceuticals are manufactured, cold chain logistics plays a crucial role in ensuring their safe and efficient distribution. Maintaining strict temperature control throughout the supply chain is vital to preserving the efficacy and safety of drug products, preventing any temperature deviations that could compromise their efficacy, quality and patient well-being

The Importance of Cold Chain Logistics in Global Pharmaceutical Shipments & Distribution

Global pharma logistics networks rely on temperature controlled logistics distribution channels to ensure product stability. Challenges in maintaining cold chain logistics integrity include:

- Extended transit times requiring robust packaging and storage solutions.

- Varying regulatory requirements across different regions impacting compliance.

- Last-mile delivery constraints requiring precise temperature control logistics.

- Infrastructure limitations in remote areas affecting cold chain capabilities.

- Supply chain disruptions from weather, customs delays, and logistics bottlenecks.

- Packaging failures leading to temperature excursions and product integrity risks.

- Energy dependence & power failures affecting cold storage and refrigerated transport.

- Technological integration & data gaps causing undetected temperature excursions.

- Skilled workforce shortages impacting safe handling of temperature-sensitive pharmaceuticals.

Best Practices for Temperature-Controlled Packaging in High-Volume Shipments

To maintain the stability of pharmaceuticals during large-scale transportation, companies must adhere to best practices, such as:

- Pre-qualified insulated containers with validated thermal performance.

- Real-time temperature tracking and monitoring for proactive issue resolution.

- Strategic distribution hubs to minimise transit times and exposure to temperature fluctuations.

- Validated packaging solutions tailored to specific temperature-sensitive products.

- Automated temperature alerts to detect fluctuations and enable quick corrective action.

- Specialised training for handlers to ensure proper management of cold chain shipments.

By leveraging cold chain logistics solutions tailored for large-scale shipments, pharmaceutical companies can ensure product efficacy from factory to pharmacy.

How CoolReach Supports Pharma Manufacturing Logistics

Unlike generic logistics providers, CoolReach Logistics specialises in temperature control logistics, offering tailored, regulatory-compliant solutions designed for the pharmaceutical sector.

Our Temperature Control Logistics Solutions:

- End-to-End Cold Chain Logistics Solutions: We provide comprehensive cold chain logistics, from raw material sourcing to final product distribution.

- Regulatory-Compliant Pharma Logistics: Our operations meet stringent GDP and MHRA requirements, ensuring compliance at every stage of the pharmaceutical logistics supply chain.

- Customised Temperature Control Packaging Solutions: We offer specialised temperature control packaging for both bulk and small-batch shipments, ensuring optimal temperature stability.

- Expert Clinical Trial Logistics & Cell & Gene Logistics Support: We ensure precise handling and secure transportation for clinical trial logistics and cell & gene logistics, providing specialised packaging and real-time monitoring.

With real-time tracking, dedicated project management, and innovative temperature control packaging, CoolReach Logistics delivers secure and efficient pharma logistics solutions tailored to the pharmaceutical sector.

Optimising Your Pharma Supply Chain with Temperature Control Logistics

Pharmaceutical manufacturers face increasing demands for precision and compliance in temperature control logistics. By leveraging cold chain logistics and temperature control packaging, companies can ensure product integrity, minimise risk, and enhance efficiency in their supply chains. Additionally, investing in reliable cold chain solutions strengthens brand reputation, builds customer trust, and reduces financial losses associated with product recalls or spoilage.

CoolReach Logistics remains a trusted partner in pharmaceutical logistics, offering tailored solutions for clinical trial logistics, cell & gene logistics, and large-scale pharmaceutical distribution.

Ready to upgrade your pharmaceutical supply chain? Contact CoolReach Logistics today for expert solutions in temperature control logistics.